Kiln Burners

Kiln Burners:

Capacity: 10 MW - 200 MW

Application: Cement kiln, Lime kiln, Mineral processing (Nickel, Ore, Bauxit, Aluminia…)

ROCKTEQ´s high impulse burners are basically characterized by:

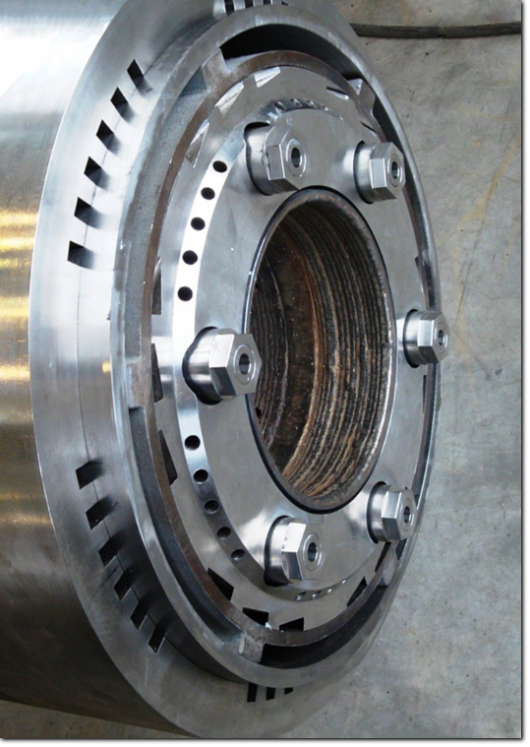

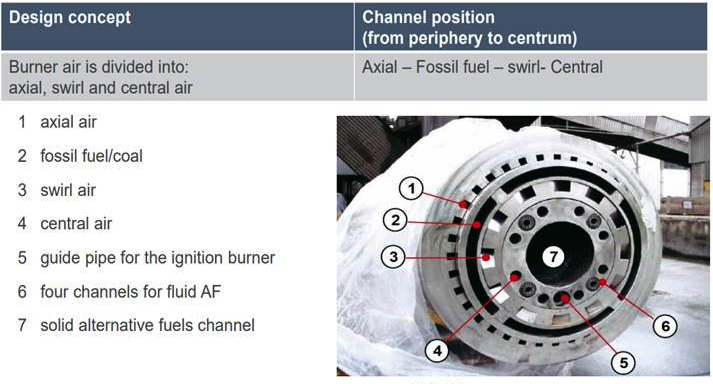

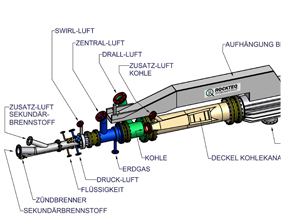

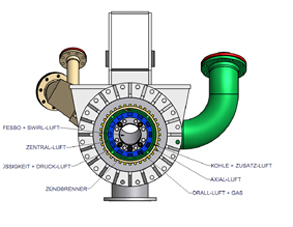

- Single air jets for enhanced recirculation with hot secondary air

- Concentric injection of all fuels and primary air components

- Adjustable central air for increased AF-Combustion (avoids double flame)

- Primary air supply by means of rotary blowers (high momentum)

- Each primary airflow and pressures are measured (prepared for full-automatic mode)

- Optimized burner diameter in relation to kiln diameter

- Modular designed burner and easy adaptable for a fuel change

- Less wear parts / low maintenance costs

Benefits:

- optimal and easy flame control of combustion by concentric channels

- independent adjustable high-pressure air flows for

- axial air

- tangential air

- central air

- AF-mixing air

- exact reproducible short and hot flame conditions

- reproducible operating conditions for clinker production

- controlled NOx emissions

- reduced electric energy consumption

- Prolonged flames by high thermal substitution rates (TSR) of AF can be controlled

- Highest AF-flexibility when using a ROCKTEQ satellite burner

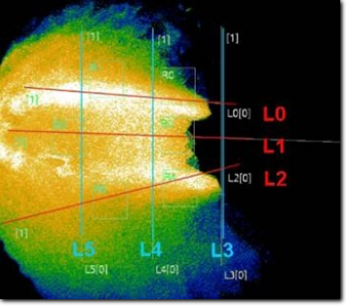

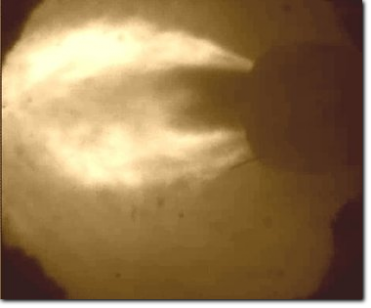

The uniform combustion of a co-axial arranged fuels is seen in the flame and on the scanner of thermography as well.

The short and hot flame is supporting a low free lime and easier grindability of clinker.

|  |  |

Design The ROCKTEQ multifuel burners are individually designed for the required fuel mix of standard fuels and alternative fuels. | Thermal Substituition Rate When working with two solid alternative fuels (SRF), we design the kiln burner and a seperate satellite injector as most suitable solution to increase the thermal substitution rate, considering the process conditions in order to maintain high clinker qualities. | AF-Booster System® The quality of SRF and RDF is important. With the aim operating with a TSR over 90%, we recommend the AF-Booster System® to receive a higher AF quality for a stable kiln operation. |

THE BURNER CONCEPT:

All our ROCKTEQ kiln burners are based on Prof. Clemente Greco´s (1937-2003) combustion research works, who lectured in Brazil at the Institute of Thermodynamics. He was the founder of kiln burner designs for hard-to-burn fuels such as petcoke.

He developed the kiln burner nozzles according to the single air jet stream design, while providing a high burner momentum, to allow a higher suction of hot secondary air into the main flame in order to increase the ignition reaction and burn-out of fuels. His studies and findings are showing the advantages of the axis-symmetric burner design.

ROCKTEQ is continuing that successful concept since 1998. Many main burner installations worldwide are proving this concept and allowing an excellent performance for clinker production even with hard-to-burn fuels.

With our operation experiance and expertise in alternative fuels combustion, we specifically design the ROCKTEQ burners and RDF preparation systems to be balanced well for operation.

We understand the mechanism of clinker production.